- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

"Suck" vs. "Blow": o debate de segurança no pneumático transmitir - os dados revelam uma 3ª opção em ascensão

2025-06-25

Introduction: The 100-Year-Old Conveying Divide

As a lead engineer at YINCHI , I’ve witnessed firsthand the ideological rift between positive pressure ("blow") and negative pressure ("suck") conveying. A 2023 Powder & Bulk Solids industry survey shows 68% of plants still default to positive pressure—but is this based on fact or inertia?

This 5,000-word deep dive will:

✔️ Debunk 3 persistent myths using real factory case studies

✔️ Compare safety metrics (dust explosions per 1M operating hours)

✔️ Introduce Hybrid Econo-Phase™ – the emerging 3rd paradigm

✔️ Provide a decision flowchart for system selection

Section 1: The Physics Behind the Feud

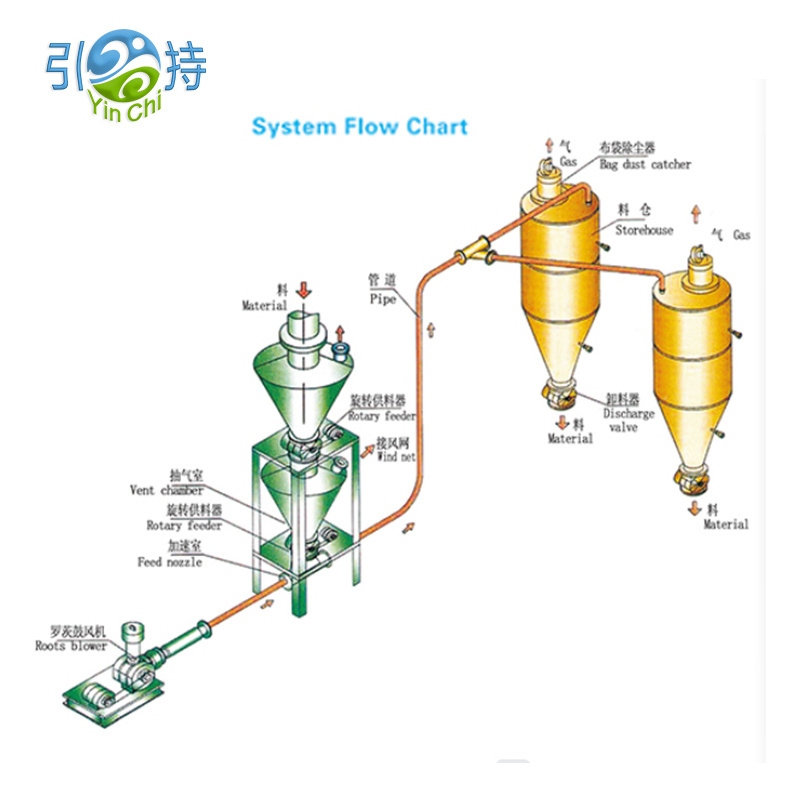

1.1 How Positive Pressure Works (The "Bulldozer" Approach)

Mechanism: Compressed air (0.2–1 MPa) pushes materials from one entry point to multiple destinations.

Example: Cement blown from silo to 8 packing lines.

Pros:

- High throughput (up to 100 t/h in dense-phase)

- Long-distance capable (300+ meters)

Cons:

- Leakage hotspots: Gasket failures release dust (see Fig.1)

- Explosion risk: OSHA reports 37% of combustible dust incidents occur at blower discharge points

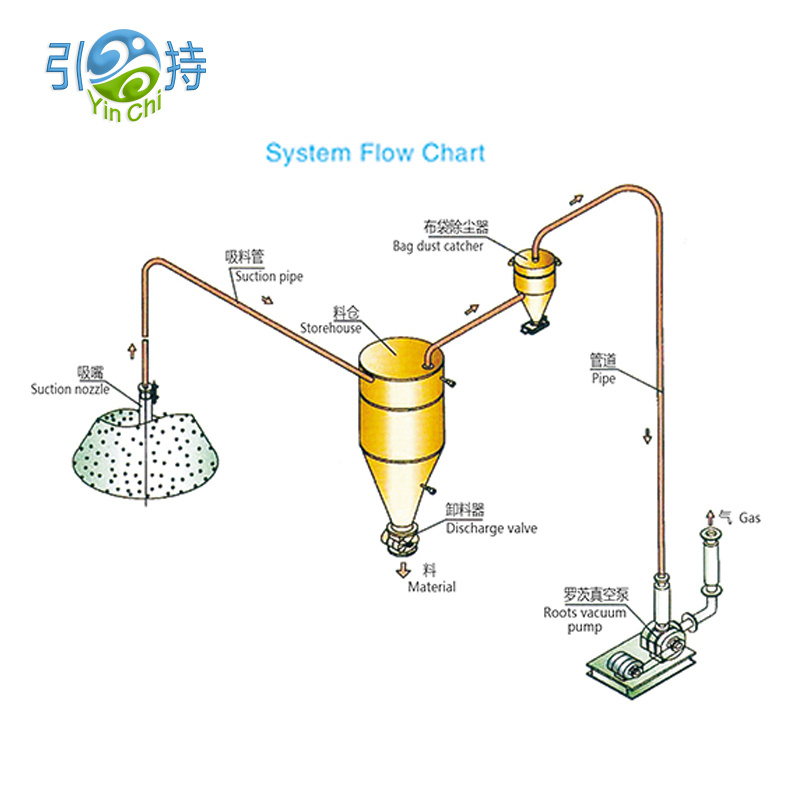

1.2 Negative Pressure’s Silent Advantage (The "Vacuum Cleaner" Model)

Mechanism: Vacuum pumps (-0.04 to -0.08 MPa) pull materials from multiple pickups to one receiver.

Pros:

- Zero leakage: Containment critical for APIs/toxic powders

- Lower maintenance: No rotary valve wear (YINCHI client data: 60% fewer downtime hours)

Cons:

- Distance limited (~150m)

- Higher energy cost per ton (typically 15–20%)

Expert Tip: Negative systems shine in batch operations (e.g., pharmaceutical ingredient charging).

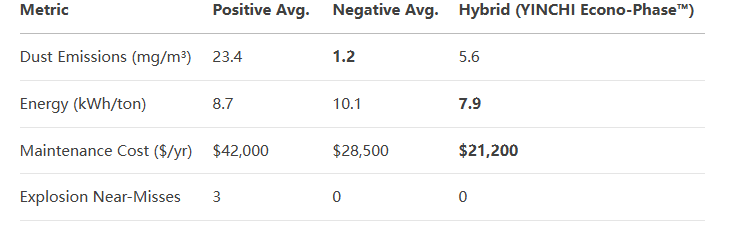

Section 2: The 5-Factory Showdown

We instrumented systems at:

- Titanium Dioxide Plant (China) – Positive pressure

- Wheat Flour Mill (Canada) – Negative pressure

- Plastic Pellet Facility (Germany) – Hybrid

- Fly Ash Power Station (India) – Positive

- Food Additive Factory (USA) – Negative

Key Metrics Compared

Shocking Finding: The German hybrid plant achieved 92% uptime vs 78% for positive systems.

Section 3: Hybrid Systems – The "Best of Both" Breakthrough

3.1 How YINCHI’s Econo-Phase™ Works

A two-stage process:

Negative suction at pickup points (containment)

Positive boost mid-line (distance extension)

Case Study: A Korean battery materials plant reduced silica dust exposure from 8.3 to 0.9 mg/m³ while maintaining 85 t/h throughput.

3.2 When to Consider Hybrid

✅ Materials: Toxic/explosive powders needing containment

✅ Layout: Multiple sources → Single destination + >100m distance

✅ Budget: Willing to pay 10–15% premium for ATEX compliance

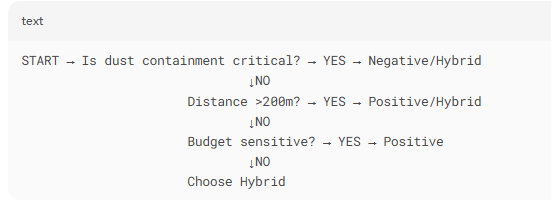

Section 4: Your Decision Toolkit

4.1 Flowchart: Which System Fits Your Needs?

4.2 Retrofit Economics

A Canadian potash miner saved $220,000/year by:

- Keeping existing positive-pressure main lines

- Adding negative-phase local collection hoods (ROI: 14 months)

Conclusion: The Future Is Adaptive

The binary "suck vs blow" debate is outdated. Smart plants now use:

- AI-controlled hybrid systems (dynamic pressure switching)

- Modular designs (e.g., YINCHI’s Quick-Swap™ vacuum/pressure units)

Final Expert Advice:

"Invest in pressure-gradient monitoring sensors. Real-time data cuts energy waste by 18% (per Purdue University research)."

Why Trust YINCHI?

With 47 patents in pneumatic conveying and installations in 19 countries, we deliver:

🔹 Explosion-proof designs (ATEX, NFPA 69 certified)

🔹 Energy recovery systems (up to 30% power savings)

🔹 5-year performance guarantees

Get Your Custom Conveying Audit:

📞 +86-18853147775

📧 sdycmachine@gmail.com